Product Description

Product Description:

AC Motor is a device that transforms the electrical energy of alternating current into mechanical energy. The AC Motor is mainly composed of an electromagnet winding or stator winding for generating magnetic field and a rotating armature or rotor. The motor is made by the phenomenon that the electric coil is forced to rotate in the magnetic field. AC motors are divided into 2 types: synchronous alternating current motor and induction motor.

The stator windings of three-phase AC motors are basically 3 coils separated by 120 degrees, which are connected by triangle or star. When three-phase current is applied, a magnetic field is generated in each coil, and the 3 magnetic fields are combined to form a rotating magnetic field.

High voltage ac motors are designed with the application of modern technology resulting in compact machines featuring excellent dynamic properties, meeting the most severe application in areas that include automation and process control.

Besides offering reliability and high performance, which will guarantee long operating periods without requiring any maintenance, the New high voltage ac motors present outstanding operating features, which include:

•Wide speed variation range

•Dimensions as per GB and IEC Standards

•High efficiency

•Low noise level

•High moment of inertia

•High capacity to dynamic loads

•Rugged construction

•High vibration resistance

•Excellent commutation quality

| Product Name | brushless AC dc servo motor for control system |

| Motor Type | DC Motor,AC Motor,Stepper Motor,Asynchronous Motor ,Synchronous Motor (Electric machinery) |

| Rotational Speed |

Low Speed/Constant Speed/High Speed/Variable Speed |

| Stator Phase Number |

Three-Phase/Single-Phase |

| Standard Features | •NEMA Premium Efficiency Level according to NEMA Y •Three-phase, 50, 60 Hz •Voltage: 3000 to 11000 V •Rated output: up to 12500 kw •Number of poles: 2 ,4,6,8,10 or 12poles •Frame sizes: 450 mm to 630mm •Cast aluminium squirrel cage for rotor •Degree of protection: IP23 to IP54(Totally enclosed) •Class insulation F with class (120ºC) temperature rise •Grease nipples for frame 450 to 630MM •Continuous Duty (S1) •With thermal protection PTC140 ºC or PT100 •Larger diameter shafts for the highest overhung load ratings in the industry •Oversized roller bearings for maximum load capacity •Other optional features under request |

| AC Motor | AC Motors can operate in high temperature, flammable and other environments, and do not need to clean the dirt of carbon brushes regularly, but it is difficult to control the speed, because it is necessary to control the frequency of AC motors (or use induction motors, increase internal resistance, reduce the motor speed at the same AC frequency. Speed, control the voltage will only affect the torque of the motor. The voltage of the general civil motor has 2 kinds, such as 110V and 220V, and there are 380V or 440V in industrial application. |

| Application | AC Motors have higher working efficiency, no smoke, odor, no pollution to the environment, and less noise. Because of its series of advantages, it is widely used in industrial and agricultural production, transportation, national defense, commercial and household appliances, medical appliances and other fields. For Example: •Compressor •Rubber mixer •Fans and Pumps •Air brower •Coal mill and rolling mill •Crushers •Conveyor belts •Centrifugal machines •Lathe •Hoist |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 8 |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

Are there different types of servo motors, and how do they differ?

Yes, there are different types of servo motors available, each with its own characteristics and applications. The variations among servo motors can be attributed to factors such as construction, control mechanisms, power requirements, and performance specifications. Let’s explore some of the common types of servo motors and how they differ:

1. DC Servo Motors:

DC servo motors are widely used in various applications. They consist of a DC motor combined with a feedback control system. The control system typically includes a position or velocity feedback sensor, such as an encoder or a resolver. DC servo motors offer good speed and torque control and are often employed in robotics, automation, and hobbyist projects. They can be operated with a separate motor driver or integrated into servo motor units with built-in control electronics.

2. AC Servo Motors:

AC servo motors are designed for high-performance applications that require precise control and fast response times. They are typically three-phase motors and are driven by sinusoidal AC waveforms. AC servo motors often incorporate advanced control algorithms and feedback systems to achieve accurate position, velocity, and torque control. These motors are commonly used in industrial automation, CNC machines, robotics, and other applications that demand high precision and dynamic performance.

3. Brushed Servo Motors:

Brushed servo motors feature a traditional brushed DC motor design. They consist of a rotor with a commutator and carbon brushes that make physical contact with the commutator. The brushes provide electrical connections, allowing the motor’s magnetic field to interact with the rotor’s windings. Brushed servo motors are known for their simplicity and cost-effectiveness. However, they may require more maintenance due to brush wear, and they generally have lower efficiency and shorter lifespan compared to brushless servo motors.

4. Brushless Servo Motors:

Brushless servo motors, also known as brushless DC (BLDC) motors, offer several advantages over brushed motors. They eliminate the need for brushes and commutators, resulting in improved reliability, higher efficiency, and longer lifespan. Brushless servo motors rely on electronic commutation, typically using Hall effect sensors or encoder feedback for accurate rotor position detection. These motors are widely used in robotics, industrial automation, aerospace, and other applications that require high-performance motion control with minimal maintenance.

5. Linear Servo Motors:

Linear servo motors are designed to provide linear motion instead of rotational motion. They consist of a primary part (stator) and a secondary part (slider or forcer) that interact magnetically to generate linear motion. Linear servo motors offer advantages such as high speed, high acceleration, and precise positioning along a linear axis. They find applications in various industries, including semiconductor manufacturing, packaging, printing, and machine tools.

6. Micro Servo Motors:

Micro servo motors are small-sized servo motors often used in applications with limited space and low power requirements. They are commonly found in hobbyist projects, model airplanes, remote-controlled vehicles, and small robotic systems. Micro servo motors are lightweight, compact, and offer reasonable precision and control for their size.

These are some of the different types of servo motors available, each catering to specific applications and requirements. The choice of servo motor type depends on factors such as the desired performance, accuracy, power requirements, environmental conditions, and cost considerations. Understanding the differences between servo motor types is essential for selecting the most suitable motor for a particular application.

How does feedback control work in a servo motor system?

In a servo motor system, feedback control plays a crucial role in achieving precise control over the motor’s position, speed, and acceleration. The feedback control loop consists of several components that work together to continuously monitor and adjust the motor’s behavior based on the desired and actual position information. Here’s an overview of how feedback control works in a servo motor system:

1. Position Reference:

The servo motor system starts with a position reference or a desired position. This can be specified by a user or a control system, depending on the application requirements. The position reference represents the target position that the servo motor needs to reach and maintain.

2. Feedback Sensor:

A feedback sensor, such as an encoder or resolver, is attached to the servo motor’s shaft. The purpose of the feedback sensor is to continuously measure the motor’s actual position and provide feedback to the control system. The sensor generates signals that indicate the motor’s current position, allowing the control system to compare it with the desired position.

3. Control System:

The control system receives the position reference and the feedback signals from the sensor. It processes this information to determine the motor’s current position error, which is the difference between the desired position and the actual position. The control system calculates the required adjustments to minimize this position error and bring the motor closer to the desired position.

4. Controller:

The controller is a key component of the feedback control loop. It receives the position error from the control system and generates control signals that govern the motor’s behavior. The controller adjusts the motor’s inputs, such as voltage or current, based on the position error and control algorithm. The control algorithm can be implemented using various techniques, such as proportional-integral-derivative (PID) control, which adjusts the motor’s inputs based on the current error, the integral of past errors, and the rate of change of errors.

5. Motor Drive:

The control signals generated by the controller are sent to the motor drive unit, which amplifies and converts these signals into appropriate voltage or current levels. The motor drive unit provides the necessary power and control signals to the servo motor to initiate the desired motion. The drive unit adjusts the motor’s inputs based on the control signals to achieve the desired position, speed, and acceleration specified by the control system.

6. Motor Response:

As the motor receives the adjusted inputs from the motor drive, it starts to rotate and move towards the desired position. The motor’s response is continually monitored by the feedback sensor, which measures the actual position in real-time.

7. Feedback Comparison:

The feedback sensor compares the actual position with the desired position. If there is any deviation, the sensor generates feedback signals reflecting the discrepancy between the desired and actual positions. These signals are fed back to the control system, allowing it to recalculate the position error and generate updated control signals to further adjust the motor’s behavior.

This feedback loop continues to operate in a continuous cycle, with the control system adjusting the motor’s inputs based on the feedback information. As a result, the servo motor can accurately track and maintain the desired position, compensating for any disturbances or variations that may occur during operation.

In summary, feedback control in a servo motor system involves continuously comparing the desired position with the actual position using a feedback sensor. The control system processes this position error and generates control signals, which are converted and amplified by the motor drive unit to drive the motor. The motor’s response is monitored by the feedback sensor, and any discrepancies are fed back to the control system, enabling it to make further adjustments. This closed-loop control mechanism ensures precise positioning and accurate control of the servo motor.

editor by CX 2024-05-17

China high quality High Precision Servo Motor for Agv Robot Parts with high quality

Product Description

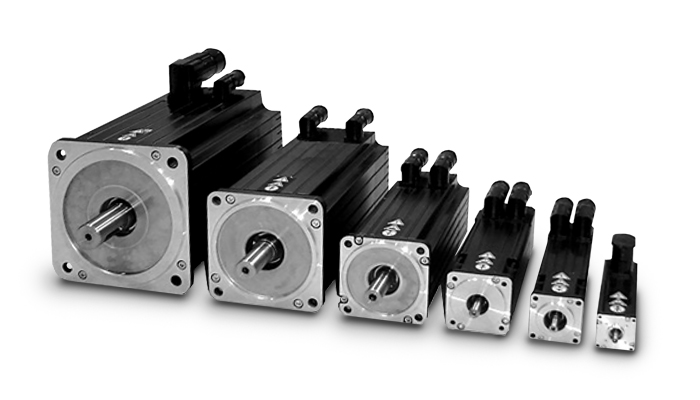

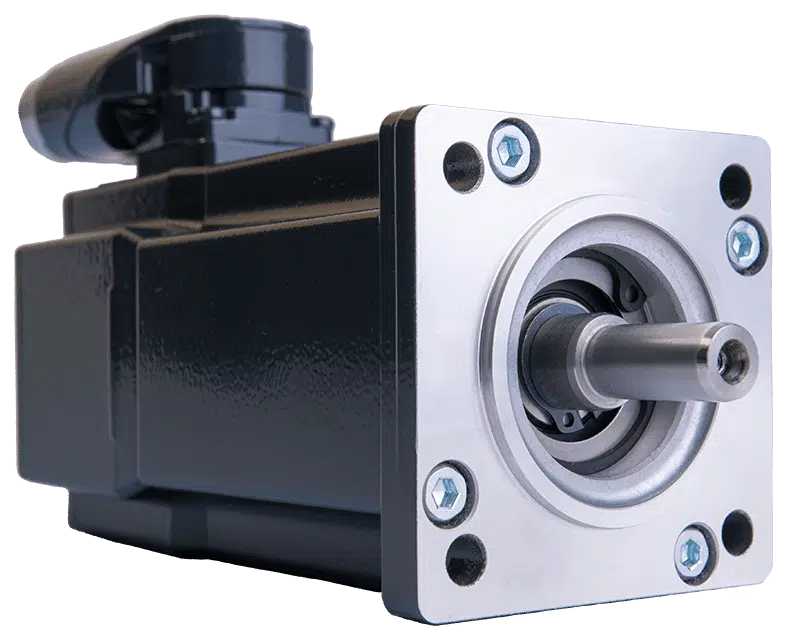

1. Pictures of the products

The motor brake is used to prevent the motor from turning when the brake is de-energized. The

most common way of using it is when the motor is used to control a vertical load, when the motor

is not enabled or powered offff, in order to prevent the mechanical mechanism driven by the motor

from shifting due to gravity and other reasons, it is necessary to use a servo motor with a brake.

2. Dimension

3. Specification

4. CE and UL Certification of Motor

5. Company Profile

HangZhou WellWit Robotics Co., Ltd was established in HangZhou in March 2015, our company focuses on research and development of mobile robot. The R&D team consists of members who experienced in field of robot, embedded hardware, software, algorithms, artificial intelligence, etc.

Currently, products for sale including moving robot, sorting robot, Auto-forklift, etc. Navigation method we provide including QR code navigation, LiDAR SLAM navigation, Visual SLAM Navigation, RTK navigation.

We focus on providing custom logistic robots for the integrators who focus on Intelligent Logistics and Intelligent Factory, and provide AGV&AMR with ODM/OEM service for global clients.

6. Certification and Case Show

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Agv Parts |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Two-Phase |

| Excitation Mode: | HB-Hybrid |

| Function: | Driving |

| Number of Poles: | 6 |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

Can you explain the concept of torque and speed in relation to servo motors?

Torque and speed are two essential parameters in understanding the performance characteristics of servo motors. Let’s explore these concepts in relation to servo motors:

Torque:

Torque refers to the rotational force produced by a servo motor. It determines the motor’s ability to generate rotational motion and overcome resistance or load. Torque is typically measured in units of force multiplied by distance, such as Nm (Newton-meter) or oz-in (ounce-inch).

The torque output of a servo motor is crucial in applications where the motor needs to move or control a load. The motor must provide enough torque to overcome the resistance or friction in the system and maintain the desired position or motion. Higher torque allows the motor to handle heavier loads or more challenging operating conditions.

It is important to note that the torque characteristics of a servo motor may vary depending on the speed or position of the motor. Manufacturers often provide torque-speed curves or torque-position curves, which illustrate the motor’s torque capabilities at different operating points. Understanding these curves helps in selecting a servo motor that can deliver the required torque for a specific application.

Speed:

Speed refers to the rotational velocity at which a servo motor operates. It indicates how fast the motor can rotate and how quickly it can achieve the desired position or motion. Speed is typically measured in units of revolutions per minute (RPM) or radians per second (rad/s).

The speed of a servo motor is crucial in applications that require rapid movements or high-speed operations. It determines the motor’s responsiveness and the system’s overall performance. Different servo motors have different speed capabilities, and the maximum achievable speed is often specified by the manufacturer.

It is worth noting that the speed of a servo motor may also affect its torque output. Some servo motors exhibit a phenomenon known as “speed-torque curve,” where the motor’s torque decreases as the speed increases. This behavior is influenced by factors such as motor design, winding resistance, and control algorithms. Understanding the speed-torque characteristics of a servo motor is important for selecting a motor that can meet the speed requirements of the application while maintaining sufficient torque.

Overall, torque and speed are interrelated parameters that determine the performance capabilities of a servo motor. The torque capability determines the motor’s ability to handle loads, while the speed capability determines how quickly the motor can achieve the desired motion. When selecting a servo motor, it is essential to consider both the torque and speed requirements of the application to ensure that the motor can deliver the desired performance.

Can servo motors be used in robotics, and if so, how are they implemented?

Yes, servo motors are commonly used in robotics due to their precise control capabilities and suitability for a wide range of robotic applications. When implementing servo motors in robotics, several factors need to be considered. Here’s an overview of how servo motors are used and implemented in robotics:

1. Joint Actuation:

Servo motors are often used to actuate the joints of robotic systems. Each joint in a robot typically requires a motor to control its movement. Servo motors provide the necessary torque and angular control to accurately position the joint. They can rotate between specific angles, allowing the robot to achieve the desired configuration and perform precise movements.

2. Position Control:

Servo motors excel at position control, which is essential for robotics applications. They can accurately maintain a specific position and respond quickly to control signals. By incorporating servo motors in robotic joints, precise positioning control can be achieved, enabling the robot to perform tasks with accuracy and repeatability.

3. Closed-Loop Control:

Implementing servo motors in robotics involves utilizing closed-loop control systems. Feedback sensors, such as encoders or resolvers, are attached to the servo motors to provide real-time feedback on the motor’s position. This feedback is used to continuously adjust the motor’s behavior and ensure accurate positioning. Closed-loop control allows the robot to compensate for any errors or disturbances and maintain precise control over its movements.

4. Control Architecture:

In robotics, servo motors are typically controlled using a combination of hardware and software. The control architecture encompasses the control algorithms, microcontrollers or embedded systems, and communication interfaces. The control system receives input signals, such as desired joint positions or trajectories, and generates control signals to drive the servo motors. The control algorithms, such as PID control, are used to calculate the appropriate adjustments based on the feedback information from the sensors.

5. Kinematics and Dynamics:

When implementing servo motors in robotics, the kinematics and dynamics of the robot must be considered. The kinematics deals with the study of the robot’s motion and position, while the dynamics focuses on the forces and torques involved in the robot’s movement. Servo motors need to be properly sized and selected based on the robot’s kinematic and dynamic requirements to ensure optimal performance and stability.

6. Integration and Programming:

Servo motors in robotics need to be integrated into the overall robot system. This involves mechanical mounting and coupling the motors to the robot’s joints, connecting the feedback sensors, and integrating the control system. Additionally, programming or configuring the control software is necessary to define the desired movements and control parameters for the servo motors. This programming can be done using robot-specific programming languages or software frameworks.

By utilizing servo motors in robotics and implementing them effectively, robots can achieve precise and controlled movements. Servo motors enable accurate positioning, fast response times, and closed-loop control, resulting in robots that can perform tasks with high accuracy, repeatability, and versatility. Whether it’s a humanoid robot, industrial manipulator, or collaborative robot (cobot), servo motors play a vital role in their actuation and control.

editor by CX 2024-05-17

China Hot selling Roboct 8 Inch DC Motor Brushless 36V Servo Motor 11A 250W with high quality

Product Description

| Size | 8 Inch Disc Brake | Size | 8 Inch Electronic Brake | |

| Rated Voltage | 36VDC | Rated Voltage | 36VDC | |

| Rated Current | 12A | Rated Current | 8A | |

| Rated Speed | 700 ±5% | Rated Speed | 680 ±5% | |

| Rated Power | 350W | Rated Power | 250W | |

| Rated Torque | 4N.m | Rated Torque | 5N.m | |

| Efficiency | ≥83% | Efficiency | ≥82% | |

| Size | 8 Inch Drum Brake | Size | 8 Inch Gear Motor | |

| Rated Voltage | 36VDC | Rated Voltage | 24VDC | |

| Rated Current | 12A | Rated Current | 11A | |

| Rated Speed | 730 ±5% | Rated Power | 250W | |

| Rated Power | 350W | Rated Torque | 12N.m | |

| Rated Torque | 5N.m | Efficiency | ≥81% | |

| Efficiency | ≥81% |

Factory and qualification

FAQ

Q: What is your company doing and where is your company?

A: HangZhou RoboCT Technological Development Co., Ltd. is dedicated to providing the disabled, the elderly and medical Rehabilitation institutes with intelligent rehabilitation devices, rehabilitation assistance and smart solutions through combining Artificial Intelligence (AI)and robotic Technology with data analysis and cloud computing. It aims to promote medical.Rehabilitation and drive the pension industry with benefiting the disabled and people with mobility impairments as its own goal. It also involves the research and products development of exoskeleton technology in several fields such as entertainment, industry and sports.

Q: What’s the difference between you and other businesses?

A: Our company has a professional design team, one-stop logistics installation team, and worry free after-sales service to provide you with convenient, safe and worry free one-stop home decoration service

Q: What are the payment methods?

A: We provide you with the bank counter transfer payment, POS machine credit card payment, cash payment and other ways

Q: What is the payment process?

A: The main process is setting dimension – scheme analysis – scheme making – determining scheme – order processing – network query – order production – Logistics Delivery

Q: What services do you all provide?

A: We provide necessary installation, configuration, simple maintenance and technical support services within our capabilities.

Q: What is the corporate of your company?

In2018, RoboCT Technology has obtained Pre-A Round Financing and introduced industrial investors. The inflow off resources has jump-start the company. The corporate culture of RoboCT Technology is “solving problems, trusting each other and keeping pace with the times” which is kept in mind by all the staff. We work to broaden humans’ perception and expand physical fitness, satisfy people’s key demands for convenient moving and a free life and loyal to the corporate vision.

Q: What is the Corporate Vision of your company?

A: Besides, we strive to improve technology and broad envision with the times, keep Leading the technology to provide better robotic products. We stick to meticulously researching and eveloping in intelligent technology. That means we will better user experience through humanistic care and persistently enhance the industry chain of exoskeleton technology. All these efforts will pave the way for us to become a leading enterprise in terms of exoskeleton around the globe. The CHINAMFG of AI has arrived, and the future is bound to be a time when humans integrate with machines. Therefore, exoskeleton must be another accessory organ for humans. All in all, a small step taken by RoboCT Technology to develop exoskeleton technology is a giant leap for mankind

Q: Whether the product can be customized?

A: Of course, we accept customized products, as long as you put CHINAMFG the demand, we will do our best.

Q: How to offer aftersales service?

A: Please contact our after-sales service personnel who will try their best to solve your after-sales problems.

Q: How can I get a quote?

A: Contact the sales, it’s necessary to know your company and project info before giving a quote, RoboCT have standard questions for you to reply. You can also email us.

Q: What’s your company advantages?

A: High cost-effective goods, high-level technology products and perfect after-sales service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial, Power Tools, Robot |

|---|---|

| Operating Speed: | Low Speed |

| Function: | Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 10 |

| Structure and Working Principle: | Brushless |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

How is the size of a servo motor determined based on application requirements?

The size of a servo motor is an important consideration when selecting a motor for a specific application. The size of the motor is determined based on various factors related to the application requirements. Let’s explore how the size of a servo motor is determined:

1. Torque Requirements:

One of the primary factors in determining the size of a servo motor is the torque requirements of the application. The motor should be able to generate sufficient torque to handle the load and overcome any resistance or friction in the system. The required torque depends on factors such as the weight of the load, the distance from the motor’s axis of rotation, and any additional forces acting on the system. By analyzing the torque requirements, one can select a servo motor with an appropriate size and torque rating to meet the application’s needs.

2. Speed and Acceleration Requirements:

The desired speed and acceleration capabilities of the application also influence the size of the servo motor. Different applications have varying speed and acceleration requirements, and the motor needs to be capable of achieving the desired performance. Higher speeds and accelerations may require larger motors with more powerful components to handle the increased forces and stresses. By considering the required speed and acceleration, one can determine the size of the motor that can meet these demands.

3. Inertia and Load Inertia Ratio:

The inertia of the load and the inertia ratio between the load and the servo motor are important considerations in sizing the motor. Inertia refers to the resistance of an object to changes in its rotational motion. If the load has a high inertia, it requires a servo motor with sufficient size and torque to accelerate and decelerate the load effectively. The inertia ratio, which is the ratio of the load inertia to the motor inertia, affects the motor’s ability to control the load’s motion accurately. A proper balance between the load and motor inertia is necessary to achieve optimal performance and stability in the system.

4. Duty Cycle and Continuous Operation:

The duty cycle and continuous operation requirements of the application also impact the motor size selection. Duty cycle refers to the ratio of the motor’s operating time to the total cycle time. Applications with high-duty cycles or continuous operation may require larger motors that can handle sustained operation without overheating or performance degradation. It is important to consider the motor’s continuous torque rating and thermal characteristics to ensure it can operate reliably under the given duty cycle requirements.

5. Physical Space Constraints:

The physical space available for installing the servo motor is another factor to consider. The motor’s dimensions should fit within the available space, considering factors such as motor length, diameter, and any mounting requirements. It is essential to ensure that the chosen motor can be easily integrated into the system without interfering with other components or causing space constraints.

6. Weight Limitations:

The weight limitations of the application may influence the motor size selection. If there are weight restrictions, such as in mobile or lightweight applications, it is necessary to choose a servo motor that is compact and lightweight while still providing the required performance. Lighter servo motors can help optimize the overall weight and balance of the system.

7. Cost Considerations:

Cost is also a factor to consider when determining the size of a servo motor. Larger motors with higher torque and performance capabilities tend to be more expensive. It is important to strike a balance between the required performance and the cost constraints of the application. Analyzing the cost-effectiveness and overall value of the motor in relation to the application requirements is essential.

By considering these factors, one can determine the appropriate size of a servo motor that can meet the specific application requirements. It is advisable to consult with manufacturers or experts in the field to ensure the chosen motor size aligns with the application needs and provides optimal performance and reliability.

In which industries are servo motors commonly used, and what applications do they serve?

Servo motors are widely used across various industries due to their precise control capabilities and ability to deliver high torque at different speeds. Here are some industries where servo motors are commonly employed, along with their applications:

1. Robotics:

Servo motors are extensively used in robotics to control the movement of robotic limbs and joints. They enable precise positioning and accurate control, allowing robots to perform tasks with high accuracy and repeatability. Servo motors are also employed in humanoid robots, industrial manipulators, and collaborative robots (cobots).

2. Manufacturing and Automation:

In manufacturing and automation industries, servo motors are used in various applications such as conveyor systems, pick-and-place machines, packaging equipment, and assembly lines. Servo motors provide precise control over the movement of components, ensuring accurate positioning, fast response times, and high throughput.

3. CNC Machining:

Servo motors play a vital role in computer numerical control (CNC) machines, where they control the movement of axes (e.g., X, Y, and Z). These motors enable precise and smooth motion, allowing CNC machines to accurately shape and cut materials such as metal, wood, and plastics. Servo motors are also used in CNC routers, milling machines, lathes, and laser cutting equipment.

4. Aerospace and Aviation:

Servo motors find applications in the aerospace and aviation industries, particularly in flight control systems. They are used to control the movement of aircraft surfaces, such as ailerons, elevators, rudders, and flaps. Servo motors ensure precise and responsive control, contributing to the stability and maneuverability of aircraft.

5. Medical Devices:

In the medical field, servo motors are used in various devices and equipment. They are employed in robotic surgery systems, prosthetics, exoskeletons, infusion pumps, diagnostic equipment, and laboratory automation. Servo motors enable precise and controlled movements required for surgical procedures, rehabilitation, and diagnostic tests.

6. Automotive:

Servo motors have several applications in the automotive industry. They are used in electric power steering systems, throttle control, braking systems, and active suspension systems. Servo motors provide accurate control over steering, acceleration, and braking, enhancing vehicle safety and performance.

7. Entertainment and Motion Control:

Servo motors are widely used in the entertainment industry for animatronics, special effects, and motion control systems. They enable realistic movements of animatronic characters, robotic props, and camera rigs in film, television, and theme park attractions. Servo motors also find applications in motion simulators, gaming peripherals, and virtual reality systems.

In addition to these industries, servo motors are utilized in various other fields, including industrial automation, renewable energy systems, textile machinery, printing and packaging, and scientific research.

Overall, servo motors are versatile components that find widespread use in industries requiring precise motion control, accurate positioning, and high torque output. Their applications span across robotics, manufacturing, CNC machining, aerospace, medical devices, automotive, entertainment, and numerous other sectors.

editor by CX 2024-05-16

China Custom Three Phase Asynchronous Servo Motor with Brake (80ST-L013030A) vacuum pump adapter

Product Description

Product characteristics

Ultra-high intrinsic coercivity, high temperature rare earth permanent,magnet material, strong resistance to magnetic energy.Using electromagnetic design optimization, aimost with the entire speed,range constant torque output,Sinusoidal magnet field design, smooth low-speed torque high overload, capability,Class F insulation, IP55 protection structure, environmental applicability, safe and reliable use.

Technical Data

| Technical Data | |||||||||

| Frame size | 60ST-L00630A | 60ST-L01330A | 60ST-L01930A | 80ST-L01330A | 80ST-L57130A | 80ST-L03330A | 90ST-L57130A | 90ST-L5710A | 90ST-L 0571 1A |

| Rated Voltage(3phase) | 220V | 220V | 220V | 220V | 220V | 220V | 220V | 220V | 220V |

| Rated Power(kw) | 0.2 | 0.4 | 0.6 | 0.4 | 0.75 | 1 | 0.75 | 0.73 | 1 |

| Rated Torque(N.m) | 0.6 | 1.3 | 1.9 | 1.3 | 2.4 | 3.3 | 2.4 | 3.5 | 4 |

| Max Torque(N.m) | 1.911 | 3.8 | 5.73 | 3.9 | 7.2 | 9.9 | 7.2 | 10.5 | 12 |

| Rated Speed(r/min) | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 2000 | 3000 |

| Rated current(A) | 1.5 | 2.8 | 3.5 | 2.6 | 4.2 | 4.5 | 3 | 3 | 4 |

| V/Krpm | 28 | 28 | 28 | 21.05 | 22.77 | 29.27 | 51 | 67 | 60 |

| Ω/phase | 11.6 | 5.83 | 3.49 | 1.858 | 0.901 | 1.081 | 3.2 | 4.06 | 2.69 |

| mH/phase | 22 | 12.23 | 8.47 | 11.956 | 6.552 | 8.29 | 7 | 9.7 | 6.21 |

| LA(mm) | 106 | 131 | 154 | 135 | 160 | 181 | 152 | 175 | 185 |

| Frame size | 110ST-L57130A | 110ST-L04030A | 110ST-L05030A | 110ST-L06571A | 110ST-L06030A | 130ST-L 0571 1A | 130ST-L 0571 1A | 130ST-L06571A | 130-7720 |

| Rated Voltage(3 phase) | 220V | 220V | 220V | 220V | 220V | 220V | 220V | 220V | 220V |

| Rated Power(kw) | 0.6 | 1.2 | 1.5 | 1.2 | 1.6 | 1 | 1.3 | 1.5 | 1.6 |

| Rated Torque(N.m) | 2.00 | 4 | 5 | 6 | 6 | 4 | 5 | 6 | 7.7 |

| Max Torque(N.m) | 6 | 12 | 15 | 18 | 18 | 13 | 15 | 18 | 23.1 |

| Rated Speed(r/min) | 3000 | 3000 | 3000 | 2000 | 3000 | 2500 | 2500 | 2500 | 2000 |

| Rated current(A) | 4 | 5 | 6 | 6 | 8 | 4 | 5 | 6 | 6 |

| V/Krpm | 23.59 | 33.74 | 33.84 | 41.39 | 30.54 | 37.72 | 38.67 | 37.34 | 47.59 |

| Ω/phase | 0.982 | 0.779 | 0.567 | 0.64 | 0.338 | 1.108 | 0.867 | 0.605 | 0.66 |

| mH/phase | 2.98 | 3.026 | 2.316 | 2.764 | 1.515 | 3.76 | 3.124 | 2.317 | 2.83 |

| LA(mm) | 158 | 189 | 204 | 217 | 217 | 165 | 173 | 183 | 197 |

| Frame size | 130ST-L5710A | 130ST-L5715A | 130ST-L5710A | 130ST-L10015A | 130ST-L10571A | 130ST-L15015A | 130ST-L15571A | 150-23571 | |

| Rated Voltage(3 phase) | 220V | 220V | 220V | 220V | 220V | 220V | 220V | 220V | |

| Rated Power(kw) | 1.6 | 2 | 2.4 | 1.5 | 2.6 | 2.3 | 3.8 | 1.6 | |

| Rated Torque(N.m) | 7.70 | 7.7 | 7.7 | 10 | 10 | 15 | 15 | 7.7 | |

| Max Torque(N.m) | 23.1 | 23.1 | 23.1 | 30 | 30 | 45 | 45 | 23.1 | |

| Rated Speed(r/min) | 2000.00 | 2500 | 3000 | 1500 | 2500 | 1500 | 2500 | 2000 | |

| Rated current(A) | 6 | 7.5 | 9 | 6 | 10 | 9.5 | 17 | 6 | |

| V/Krpm | 47.59 | 40.03 | 32.22 | 64.89 | 38.76 | 68.13 | 34.07 | 47.59 | |

| Ω/phase | 0.66 | 0.454 | 0.282 | 0.801 | 0.262 | 0.458 | 0.102 | 0.66 | |

| mH/phase | 2.83 | 1.913 | 1.232 | 3.675 | 1.258 | 2.369 | 0.598 | 2.83 | |

| LA(mm) | 197 | 197 | 197 | 218 | 218 | 263 | 263 | 197 | |

| Frame size | 150ST-L15571A | 150ST-L18571A | 150ST-L23571A | 150ST-L27571A | 180ST-L19571A | 180ST-L23571A | 180ST-L31018A | ||

| Rated Power(KW) | 3.8 | 3.6 | 4.7 | 5.5 | 4 | 5 | 6 | ||

| Rated Torque(N.m) | 15 | 18 | 23 | 27 | 19 | 23 | 31 | ||

| Rated Speed(rpm) | 2500 | 2000 | 2000 | 2000 | 2000 | 2000 | 1800 | ||

| Rated Current(A) | 16.5 | 16.5 | 20.5 | 20.5 | 16.8 | 28 | 22 | ||

| Max Torque(N.m) | 45 | 54 | 69 | 81 | 57.3 | 71.6 | 79.5 | ||

| Voltage(V) | 220 | 220 | 220 | 220 | 220 | 220 | 220 | ||

| Frame size | 190ST-H44017A | 190ST-H56017A | 190ST-H76015A | 190ST-H95015A | 230ST-H11415A | 230ST-H14615A | 230ST-H19115A | 230ST-H23515A | 130-7720 |

| Rated Power(KW) | 8 | 10 | 12 | 15 | 18 | 23 | 30 | 37 | 220V |

| Rated Torque(N.m) | 44 | 56 | 76 | 95 | 114 | 146 | 191 | 235 | 1.6 |

| Rated Speed(rpm) | 1700 | 1700 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 7.7 |

| Rated Current(A) | 17.5 | 20.1 | 27 | 34 | 44.1 | 52.8 | 68.5 | 83.4 | 2000 |

| Efficiency | 90.5 | 91.1 | 91.6 | 92.1 | 92.5 | 93 | 93.6 | 94.2 | |

| Voltage(V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 47.59 |

| Rotor Inertia(Kg.cm2) | 0.01 | 0.014 | 0.016 | 0.019 | 0.035 | 0.045 | 0.056 | 0.071 | |

| weight(kg) | 38.8 | 43.8 | 49.5 | 54.7 | 73 | 88 | 105 | 122 | |

For further informations,pls visit our web page without hesitate!

Contact Information:

hongma /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

Can you explain the concept of torque and speed in relation to servo motors?

Torque and speed are two essential parameters in understanding the performance characteristics of servo motors. Let’s explore these concepts in relation to servo motors:

Torque:

Torque refers to the rotational force produced by a servo motor. It determines the motor’s ability to generate rotational motion and overcome resistance or load. Torque is typically measured in units of force multiplied by distance, such as Nm (Newton-meter) or oz-in (ounce-inch).

The torque output of a servo motor is crucial in applications where the motor needs to move or control a load. The motor must provide enough torque to overcome the resistance or friction in the system and maintain the desired position or motion. Higher torque allows the motor to handle heavier loads or more challenging operating conditions.

It is important to note that the torque characteristics of a servo motor may vary depending on the speed or position of the motor. Manufacturers often provide torque-speed curves or torque-position curves, which illustrate the motor’s torque capabilities at different operating points. Understanding these curves helps in selecting a servo motor that can deliver the required torque for a specific application.

Speed:

Speed refers to the rotational velocity at which a servo motor operates. It indicates how fast the motor can rotate and how quickly it can achieve the desired position or motion. Speed is typically measured in units of revolutions per minute (RPM) or radians per second (rad/s).

The speed of a servo motor is crucial in applications that require rapid movements or high-speed operations. It determines the motor’s responsiveness and the system’s overall performance. Different servo motors have different speed capabilities, and the maximum achievable speed is often specified by the manufacturer.

It is worth noting that the speed of a servo motor may also affect its torque output. Some servo motors exhibit a phenomenon known as “speed-torque curve,” where the motor’s torque decreases as the speed increases. This behavior is influenced by factors such as motor design, winding resistance, and control algorithms. Understanding the speed-torque characteristics of a servo motor is important for selecting a motor that can meet the speed requirements of the application while maintaining sufficient torque.

Overall, torque and speed are interrelated parameters that determine the performance capabilities of a servo motor. The torque capability determines the motor’s ability to handle loads, while the speed capability determines how quickly the motor can achieve the desired motion. When selecting a servo motor, it is essential to consider both the torque and speed requirements of the application to ensure that the motor can deliver the desired performance.

How does feedback control work in a servo motor system?

In a servo motor system, feedback control plays a crucial role in achieving precise control over the motor’s position, speed, and acceleration. The feedback control loop consists of several components that work together to continuously monitor and adjust the motor’s behavior based on the desired and actual position information. Here’s an overview of how feedback control works in a servo motor system:

1. Position Reference:

The servo motor system starts with a position reference or a desired position. This can be specified by a user or a control system, depending on the application requirements. The position reference represents the target position that the servo motor needs to reach and maintain.

2. Feedback Sensor:

A feedback sensor, such as an encoder or resolver, is attached to the servo motor’s shaft. The purpose of the feedback sensor is to continuously measure the motor’s actual position and provide feedback to the control system. The sensor generates signals that indicate the motor’s current position, allowing the control system to compare it with the desired position.

3. Control System:

The control system receives the position reference and the feedback signals from the sensor. It processes this information to determine the motor’s current position error, which is the difference between the desired position and the actual position. The control system calculates the required adjustments to minimize this position error and bring the motor closer to the desired position.

4. Controller:

The controller is a key component of the feedback control loop. It receives the position error from the control system and generates control signals that govern the motor’s behavior. The controller adjusts the motor’s inputs, such as voltage or current, based on the position error and control algorithm. The control algorithm can be implemented using various techniques, such as proportional-integral-derivative (PID) control, which adjusts the motor’s inputs based on the current error, the integral of past errors, and the rate of change of errors.

5. Motor Drive:

The control signals generated by the controller are sent to the motor drive unit, which amplifies and converts these signals into appropriate voltage or current levels. The motor drive unit provides the necessary power and control signals to the servo motor to initiate the desired motion. The drive unit adjusts the motor’s inputs based on the control signals to achieve the desired position, speed, and acceleration specified by the control system.

6. Motor Response:

As the motor receives the adjusted inputs from the motor drive, it starts to rotate and move towards the desired position. The motor’s response is continually monitored by the feedback sensor, which measures the actual position in real-time.

7. Feedback Comparison:

The feedback sensor compares the actual position with the desired position. If there is any deviation, the sensor generates feedback signals reflecting the discrepancy between the desired and actual positions. These signals are fed back to the control system, allowing it to recalculate the position error and generate updated control signals to further adjust the motor’s behavior.

This feedback loop continues to operate in a continuous cycle, with the control system adjusting the motor’s inputs based on the feedback information. As a result, the servo motor can accurately track and maintain the desired position, compensating for any disturbances or variations that may occur during operation.

In summary, feedback control in a servo motor system involves continuously comparing the desired position with the actual position using a feedback sensor. The control system processes this position error and generates control signals, which are converted and amplified by the motor drive unit to drive the motor. The motor’s response is monitored by the feedback sensor, and any discrepancies are fed back to the control system, enabling it to make further adjustments. This closed-loop control mechanism ensures precise positioning and accurate control of the servo motor.

editor by CX 2024-05-16

China manufacturer St Series Permanent Magnet Servo Motor with Electric Hydraulic 380V 5.5kw~110kw vacuum pump connector

Product Description

product/SxBUgoVvCakW/China-Y-IP23-Series-AC-Electric-Motor-for-Plastic-Machine.html

Xihu (West Lake) Dis. Xihu (West Lake) Dis.i Motor Co.,Ltd which was founded in 1969, is national appointed as chief factory for small and medium-size motor by machinery ministry. It has 50 years history of producing electric Motor.In November 2 square meter’s workshop,8200 square meter’s technology Research building, 23 assembly lines and 2300 sets of producing Machines, and motor testing center (10000KW).The main electric motors for technical research are high-efficiency motor with energy saving, VFD motor, large-size motor and special motor. The company has 1200 staff and workers in total, there are 130 engineers who work on scientific, technical research and test development, Which build “ZheJiang technical center”, “ZheJiang Electrical Engineering Center “. The company passes ISO9001:2008, ISO14001:2004, GB/T28001.

Main products: high-efficiency motor (YE3 80-355, YE2 56-355), High-efficiency high voltage motor (YX/YXKK/YXKS series H355-800),compact high voltage motor (YX2 H355-560), VFD motor (YVF2 series H80-450),high voltage VFD motor, low voltage rotor motor (YR series H315-355),YR/YRKK high voltage rotor motor, high-efficiency explosion-proof motor (YB3 series H80-355),TDMK series large-size synchronous motor (specified for mine mill), high voltage explosion-proof motor (YB2 H355-560), Y2 series low voltage big power motor, permanent magnet synchronous motor, YE4 series super premium efficiency motor, special motor for car and other special motors for customers. YE3,JHM,YVF2, YE2 series motors pass “CCC” certificates; YE2, YE3 series high-efficiency motors get “CE” certificates; YE3 premium efficiency motor, CXYT permanent magnet synchronous motor, S18/25 get National energy-saving certificates.

In year 2016, the company achieved sales revenue RMB 1.52 billion Yuan, incoming tax RMB 60 million yuan, net profit RMB 10.171 million yuan, and top 3 comprehensive strength in field of small-medium electric motors in China.

Technical Parameters

| Rated voltage | 220V,380V |

| Output power | 5.5kw~110KW |

| Rated torque | 35~480N.m |

| Rated speed | 1000~3000rpm |

| Flange Stop | 180,250 |

| Cooling Methond | Air cooling,water cooling |

| Protection Class | IPSS |

| Insulation Class | F/H temperature rise B |

| Altitude | Not exceed 1000m meters |

| Rated frequency | 50HZ |

| Ambiemt temperature | -20°C~+40°C |

The above is The Default Parameters, If you have any other special requirements, you can contact us for Customization.

Q: Are you a factory or trading company?

A: HangZhou XIHU (WEST LAKE) DIS.I is a factory that has been focusing on motors and accessories for more than 50 years.

Q: What about the warranty?

A: We offer 12 month warranty period as the quality guarantee.

Q: Can you do OEM?

A: Yes , we offer OEM.

Q: How about your service?

A: We have pre-sale service, in-sale service and after-sale service.What we pursue is long-term cooperation,

so our principle is customer first.

Q: What are your terms of delivery?

A: Generally we ship in FOB term, but we couldoffer the solution for CNF, CIF and DDP, which all based on your

requirement.

Q: What’s the delivery time?

A: 10 to 30 days after receiving your payment in advance. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Open Type |

| Number of Poles: | 2 |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

How does the accuracy of a servo motor impact the precision of a system it operates in?

The accuracy of a servo motor has a significant impact on the precision of the system in which it operates. Here’s how the accuracy of a servo motor influences the precision of the system:

1. Positioning Control:

The accuracy of a servo motor directly affects the precision of positioning control in a system. A servo motor with high accuracy can accurately and consistently reach and maintain the desired position. This precision in positioning control is crucial in applications where precise movements, such as in robotics or manufacturing processes, are required. If the servo motor lacks accuracy, it may introduce position errors, leading to reduced precision in the system’s overall operation.

2. Repeatability:

Repeatability refers to the ability of a system to consistently achieve the same position or motion repeatedly. The accuracy of a servo motor plays a vital role in achieving high repeatability. A servo motor with high accuracy will consistently return to the same position when commanded to do so. This level of repeatability is essential in applications where consistent and precise movements are necessary, such as in assembly lines or pick-and-place operations. A lack of accuracy in the servo motor can result in variations in position from one cycle to another, reducing the overall precision of the system.

3. Error Compensation:

The accuracy of a servo motor is crucial for error compensation in a system. In many applications, external factors, such as variations in load or environmental conditions, can introduce errors in the system’s operation. An accurate servo motor can help compensate for these errors by precisely adjusting its position or motion based on feedback from sensors. This error compensation capability contributes to maintaining the precision of the system, as the servo motor can continuously adjust to minimize any deviations from the desired position or trajectory.

4. System Stability:

The accuracy of the servo motor also impacts the stability of the system. A servo motor with high accuracy can achieve stable movements and maintain control over the system’s dynamics. It can respond accurately to control signals, preventing overshoot, oscillations, or erratic behaviors that can degrade system precision. On the other hand, a servo motor with lower accuracy may introduce instability or erratic movements, compromising the overall precision of the system.

5. System Calibration and Calibration:

An accurate servo motor simplifies the calibration and fine-tuning process of a system. When a system requires calibration, an accurate servo motor provides a reliable reference point for adjustments. The precise and consistent movements of the servo motor make it easier to calibrate other components or subsystems in the system, ensuring that the entire system operates with the desired precision. If the servo motor lacks accuracy, it can be challenging to calibrate the system effectively, resulting in reduced precision in the system’s operation.

In summary, the accuracy of a servo motor has a direct impact on the precision of the system it operates in. An accurate servo motor enables precise positioning control, high repeatability, effective error compensation, system stability, and simplified calibration processes. These factors collectively contribute to achieving the desired precision in the system’s operation. Therefore, selecting a servo motor with the appropriate level of accuracy is crucial for ensuring the overall precision and performance of the system.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-05-16

China OEM 80mm 48V/220V 500W-750W Brushless DC BLDC Servo Motor vacuum pump belt

Product Description

Note:

The specifications can be designed according to the customer’s requirements!

Option:

Customized shaft, performance, voltage, lead wires…

Application:

swimming pool, automotive, semiconductor, chemical & medical, industrial automation, power tool, medical instrument, measuring equipment, office automation, various OEM application.

Parameter:

| Motor Model | BS | BS801-16033 | BS801-23950 |

| Number of Phases | 3 | 3 | 3 |

| Number of Poles | 8 | 8 | 8 |

| Rated Voltage(VDC/VAC) | 48 | 220 | 220 |

| Rated Speed(Rpm) | 3000 | 3000 | 3000 |

| Rated Torque(N.m) | 1.6 | 1.6 | 2.39 |

| Rated Power(W) | 500 | 500 | 750 |

| Rated Current(A) | 14 | 3.3 | 5.0 |

| Peak Current(A) | 42 | 10 | 15.0 |

| Peak Torque(N.M) | 4.8 | 4.8 | 7.1 |

| Rotor Inertia(kg.cm2) | 1.6 | 1.6 | 2.1 |

| Torque Constant(N.m/A) | 0.11 | 0.51 | 0.51 |

| Torque Constant(V/krpm) | 10.47 | 40 | 42 |

| Line-Line Resistance(Ω) | 1 | 3 | 2.2 |

| Line-Line Inductance(mH) | 0.9 | 6 | 9 |

| Length(mm) L | 96 | 96 | 116 |

| Weight(kg) | 2.04 | 2.2 | 3.2 |

| Encoder line number (ppr) | 1000,2500 | ||

About Us:

I.CH motion co., LTD, headquartered in HangZhou, is a professional manufacturer and supplier of the motor. We have provided BLDC motor, BLDC Gear motor, BLDC Servo motor since 2006, which are widely used in medical equipment, automation equipment, automobile industry, and 3D printer.

As a professional manufacturer who has professional teams, we can custom according to your needs.

Certificate:

IOS9001, CE…

Service:

1, OEM & ODM service.

2, One-year guarantee.

Shipping:

1, Carton, Pallet, or what you want.

2, The Delivery time is about 30-45 days.

Customer’s Visiting:

FAQ:

1, Are you a factory?

Yes, we have been in designing and providing excellent motors for customers.

2, Can you provide a sample?

Yes.

3, How long you could prepare samples?

If customized one, about a week around.

4, If My package has missing products. What can I do?

Please contact our support team and we will confirm your order with the package contents. We apologize for any inconvenience. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Power Tools |

|---|---|

| Operating Speed: | Low Speed |

| Function: | Control, Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

| Structure and Working Principle: | Brushless |

| Customization: |

Available

|

|

|---|

How does the cost of servo motors vary based on their specifications and features?